Hands-on Practice Activities

A hands-on activity is an instructional technique that allows participants to learn by doing. During a hands-on activity participants are directly involved in their learning. Participants get direct practical experience as they apply their learning and learn from their failures. Hands-on learning is appropriate for both physical and mental skills and tasks.

Hands-on learning provides many benefits. Studies have shown that participants, who are given the chance to practice what they have learned, retain 75% of the information presented. The transfer of learning to the workplace is high with hands-on activities because the materials and equipment are the same as what they will be using on the job. Because the learning is relevant and immediate, participants in a hands-on learning environment are highly engaged and motivated. Hands-on learning also supports critical thinking and problem-solving skills as participants are expected to be more self-reliant as they work through the activity.

There are also disadvantages to hands-on learning activities. While the activity demonstration will focus on key skills, you still need to troubleshoot issues and answer a wide range of participant questions. Often, you will find that more than one instructor is needed. The primary instructor presents the demonstration and the other(s) circulate around checking in on participants’ progress and answering questions. Also, hands-on training is sometimes rushed. Participants may find they do not get enough practice opportunities to memorize the steps. If you create a high-quality job aid to guide participants during the training, you can help them recall the correct sequence or procedure when they are back on the job.

For more ideas on how to use job aids to support participant learning, refer to Job Aids.

Instructions

How to conduct an effective hands-on activity:

- (Optional) Distribute and describe how to use the job aid designed for the task, technique, or procedure.

- Demonstrate how to perform the task, technique, or procedure. Explain what you are doing and pause to demonstrate the steps. Refer to the job aid when appropriate.

- Ask participants to turn and describe the process to their partner. This helps participants internalize what they have learned. It also serves as a knowledge check as they can verify their memories of details with their partner.

- Ask participants questions about the key points of the demonstration. Answer participant questions.

- Monitor and provide guidance as participants practice performing the task, technique, or procedure.

- Provide both positive and corrective feedback so participants understand when they did something right and when they made mistakes.

- Allow participants to practice until they can perform the action without any errors.

Example

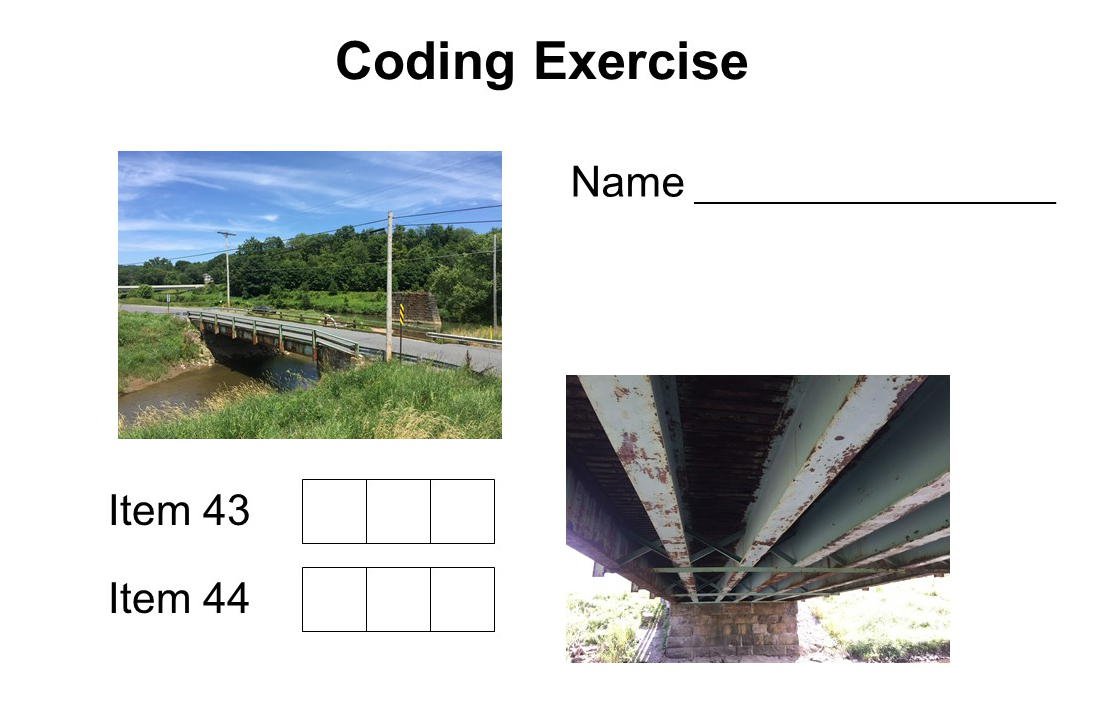

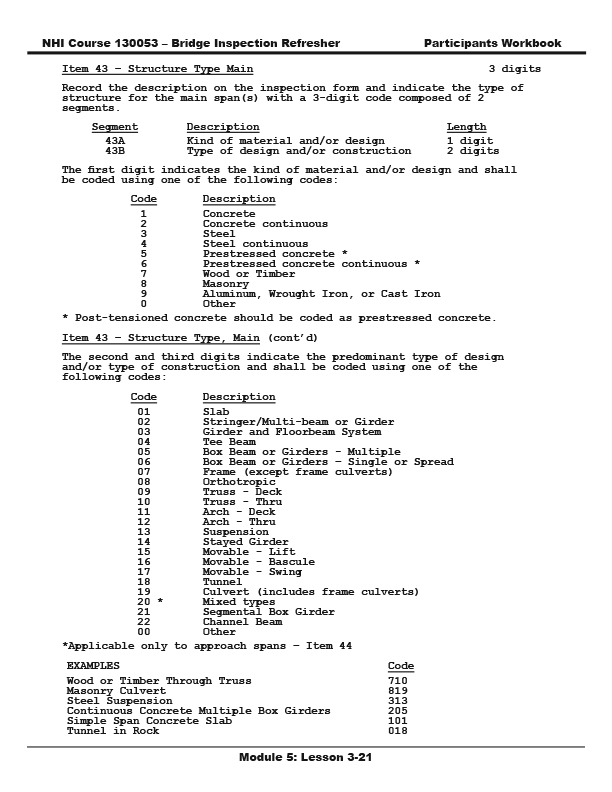

In the NHI “Bridge Inspector Refresher Training” course, participants practice selecting the appropriate codes for structure inventory and appraisal and structure type for the National Bridge Inventory (NBI). For his NHI “Instructor Development Course” training presentation, “Superstructure Type Identification,” Patrick Kane created a job aid for a hands-on activity using a page from the participant workbook. Figure 31 displays the practice coding worksheet Kane created for his training presentation. Figure 32 displays the job aid for used in the NBI coding activity.

Source: Kane (2018).

Source: NHI (n.d.)

Instructor-Led Training

If the practice activity is complex, you can ask participants to work with a partner or in a table group to complete it. Facilitate the collaboration by providing only one set of documentation so that participants have to get out of their chairs in order to work together.

Web Conference Training

If participants will be working independently, provide a Worked Example or Job Aid to follow. Give participants a way to contact the instructor directly if they have any questions or difficulties while completing the activity.